Notre savoir-faire

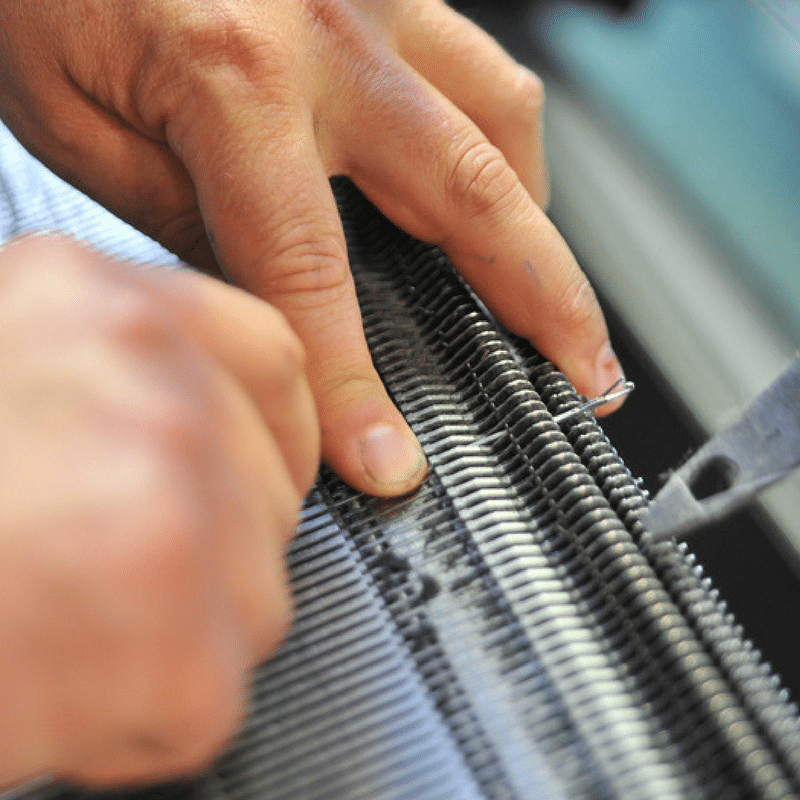

Depuis 1973, les équipes des ateliers pérennisent les savoir-faire en tricotage et en confection de la manufacture. Passionnés par leur métier, 42 personnes travaillent sur notre site de Castres (81). Des hommes et des femmes soucieux de fabriquer des pulls de qualité. Certains sont là depuis plus de 30 ans.

Nos étapes de production

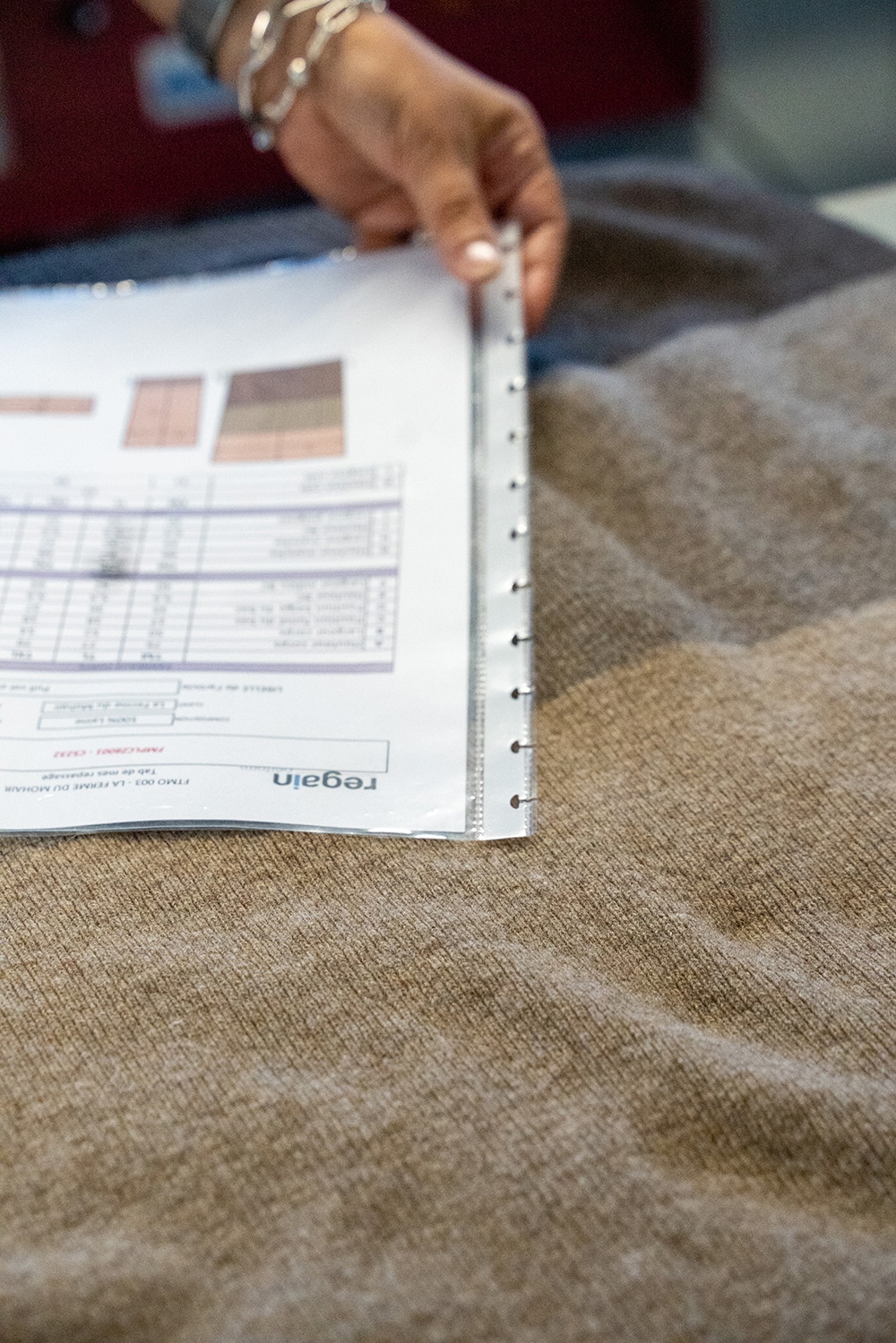

Patronage

Tricotage

Pose du col

Coupe

Lavage

Montage / assemblage

Repassage

Nos engagements et certifications

Dès 2010, la manufacture s'engage dans une démarche active de développement durable. Toutes les étapes du processus ont été revues pour répondre à une préoccupation d'économie circulaire : optimisation dès la conception des produits, recyclage des chutes et reprise des pulls en fin de vie. Les fils ainsi récupérés sont envoyés chez des filateurs locaux qui peuvent alors élaborer des fils recyclés.

Qualité Iso9001

Un leitmotiv : la qualité

En 1996, la manufacture obtient la certification AFAQ ISO 9001 qui récompense la rigueur des processus appliqués dans la conception et la fabrication de ses pulls. L'héritage de son expérience de 50 ans sur les marchés professionnels confère aux pull-overs une qualité irréprochable : les couleurs, les matières, le toucher, les formes ont une tenue remarquable.

UN Global Compact

En 2018, notre manufacture poursuit sa démarche proactive et s’engage dans l'initiative de responsabilité des entreprises du Pacte mondial des Nations unies et ses principes dans les domaines des droits de l'homme, du travail, de l'environnement et de la lutte contre la corruption.

Origine France garantie

Regain, le pull 100% Français

Les pulls de la manufacture sont made in France, tricotés et confectionnés à Castres. En 2014, l’entreprise obtient le Label Origine France. Ce label a pour objectif, d’une part, de donner aux consommateurs une information claire sur l’origine d’un produit et, d’autre part, de permettre aux entreprises qui font cette démarche de certification, de valoriser leur production. Pour obtenir ce label, le produit fabriqué doit respecter les deux critères suivants :

- Le lieu où le produit prend ses caractéristiques essentielles est situé en France

- 50% au moins du prix de revient unitaire est acquis en France.

Collectif Tricolor

Un acteur engagé

Laurent Brunas croit à une mode de bon sens et à des pièces qui durent. Pour cela la manufacture est un membre fondateur du collectif Tricolore qui défend les laines locales françaises et qui a pour objectifs :

- de faire dialoguer les acteurs de l’élevage ovin, de l’industrie et de la distribution

- de construire une vision commune, durable, équitable et viable

- de mettre en place un programme collectif pour augmenter la valorisation et l’usage des laines de tonte françaises.

Entreprise du patrimoine vivant

Notre manufacture labellisée Entreprise du Patrimoine Vivant

Ce prestigieux label d’état distingue les entreprises Françaises aux savoir-faire artisanaux et industriels d’excellence. Il reconnaît notre savoir faire complexe et rare comme le tricotage, le ravaudage, le remaillage. Mais aussi notre engagement à maintenir et transmettre nos savoir-faire et innover pour pérenniser notre manufacture. Ancrée dans son territoire depuis 1973, notre manufacture est reconnue pour son engagement en tant que fabricant responsable et pour sa contribution au circuit court avec les laines de France. Pour y prétendre, il faut d’abord constituer un dossier auprès de l’INMA (Institut National des Métiers d’Arts), puis passer un audit et attendre le verdict. Le tout prend environ 18 mois. Nous sommes très honorés de cette confiance.

Des clients prestigieux

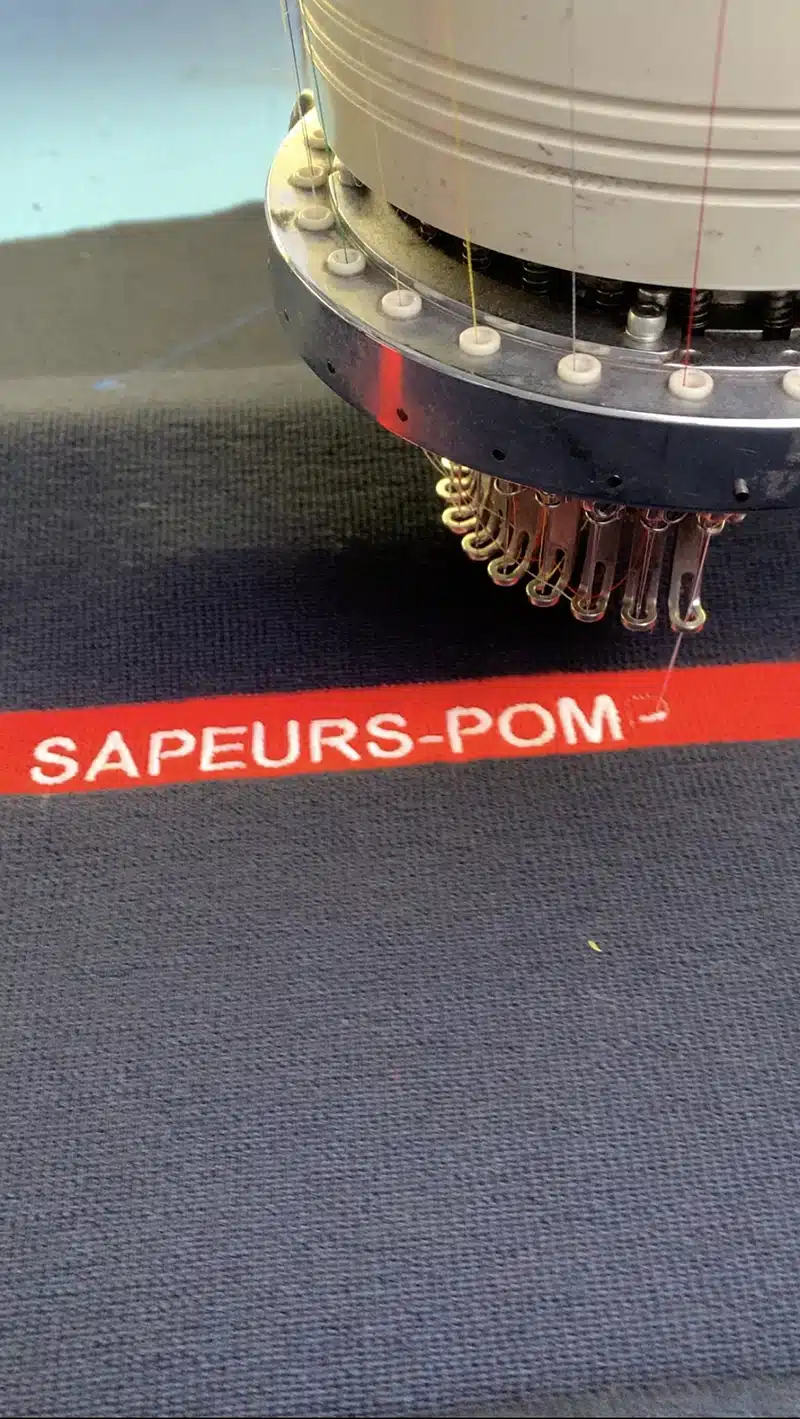

Chez Regain la maille est notre métier, nos ateliers la travaillent depuis 1973. Dans notre usine de Castres nous tricotons les meilleurs fils, dans les plus belles mailles. Vous pouvez bénéficier de notre savoir-faire de 50 ans sur des marchés très exigeants sur le plan qualitatif tels que les sapeurs-pompiers, l’armée ou encore la gendarmerie.

Notre passion et notre exigence nous permettent de fabriquer pour les entreprises privées tout comme pour des marques de mode.